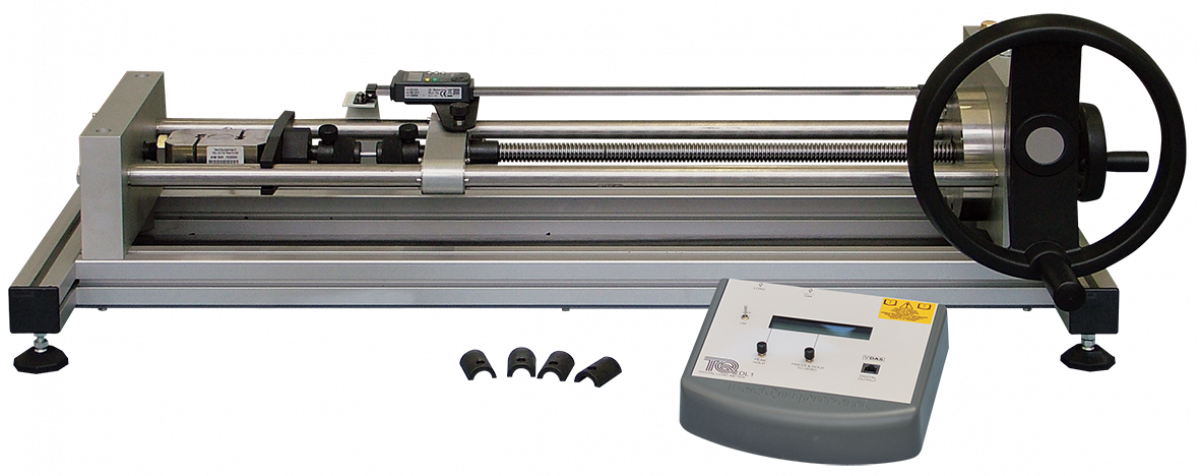

Key Features:

- Bench-top tensile testing machine designed for student use

- Simple hand-operated load application for safe and easy operation

- Digital displays of load and overall displacement

- Supplied with chucks for standard 20 mm2 specimens

- Complements TecQuipment’s Torsion Testing Machine (SM1001)

- Optional Extensometer (SM1002a) for Young’s modulus tests

- Optional Compression Cage (SM1002b) and Brinell Test Set (SM1002c)

- Works with TecQuipment’s Versatile Data Acquisition System (VDAS®)

Description:

- A small-scale machine that fits on a bench-top and allows simple tensile tests of metal specimens up to a maximum load of 20 kN. This machine is a good partner to TecQuipment’s Torsion Testing Machine (SM1001).

- The machine has an extruded aluminium bed that holds the load application and load measuring mechanisms. ‘Tie bars’ add rigidity to the structure. The load application mechanism includes a hand-driven worm-and-wheel gearbox, driving a lead screw with approximately 400 mm of travel. The mechanism uses ball races and self-aligning ball thrust races in the direction of loading. These low-friction bearings, with the large handwheel allow the user to apply maximum load with minimum effort. They also give smooth and progressive operation, necessary to help the user apply a steady strain rate for best results.

- The unit also has a smaller “quick advance” handwheel that allows the user to set the distance between the chucks simply and quickly before each test.

- The load measuring mechanism is a strain-gauged load cell that connects to a microprocessor-controlled digital display. The load display unit has a ‘peak hold’ function to register the maximum load before the specimen breaks. A sliding digital display measures the tensile displacement (extension) over the entire movement. An optional precision extensometer (SM1002a) is available for increased strain measurement accuracy to allow measurements of the material’s Young’s Modulus. Both the load, extension and extensometer displays can connect to TecQuipment’s optional VDAS®.

- The tensile specimens mount between the load application mechanism and load cell, in collet chucks via ball-jointed spigots. This ensures purely axial loading. The equipment includes collet chucks to fit both the long and short style of TecQuipment’s 20mm2 specimens.

- TecQuipment supply a starter set of tensile specimens with the machine, made of two different carbon steel alloys (each in their ‘as drawn’ and their annealed condition), brass and aluminium. TecQuipment can also supply extra specimens (contact our sales team for details). The User Guide includes drawings to allow the user to make their own specimens if needed.

- For quick and reliable tests, TecQuipment’s optional VDAS® gives accurate real-time data capture, monitoring and display, calculation and charting of all important readings on a computer (computer not included).

Learning Outcomes:

- Tensile tests up to 20 kN on specimens made of different metals, to find material characteristics such as upper and lower yield strengths, tensile strength and overall extension.

- Tests of Young’s modulus (E) for the specimen material (needs SM1002a and TL specimens)

Specifications

- Dimensions: 1100 mm long x 350 mm high x 400 mm wide

- Weight: 41.5 kg (including display unit)

- Digital Displays:

- Load – display resolution of 0.01 kN

- Extension – display resolution of 0.01 mm

- Tensile Test specimens included (60 in sets of 10):

- 0.1% carbon steel (as drawn) (TL1010 and TS1010)

- 0.4% carbon steel (as drawn) (TL1011 and TS1011)

- 0.1% carbon steel (normalised) (TL1020 and TS1020)

- 0.4% carbon steel (normalised) (TL1021 and TS1021)

- Aluminium (TL1030 and TS1030)

- Brass (TL1040 and TS1040)

- Each set of ten specimens has 5 x long (TL) specimens and 5 x short (TS) specimens.

For details see the catalog below: