INVERSE MAGNETOSTRICTIVE TORQUE SENSORS – Episode 2

In the episode 1, we have got a overview about inverse magnetostrictive torque sensors. In this episode, we are going to learn more about NCTE sensors and their advatages.

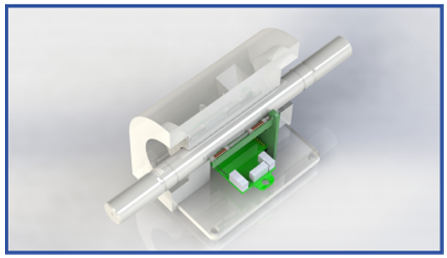

A non-contact torque and force sensor consists of the magnetised existing shaft (primary sensor) and a reading unit (secondary sensor) whose design depends on the application. This paragraph explains the sensor design in detail based on the phases of its production.

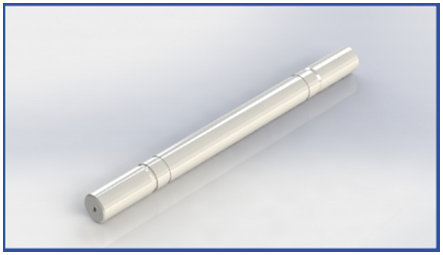

The shaft as primary sensor

The central element of the non-contact sensor is the component transmitting the torque or force. This may be a shaft in an extruder, a steering wheel or a car’s gearbox.

Since shafts go through various steps in production they may have been magnetised already, for instance by induction hardening or magnetic clamping fixtures. For getting a uniform basic state for later magnetisation the shaft will therefore be cleaned first and then demagnetised (step 1).

Then the shaft will get magnetic encoding by means of a process called Pulse Current Magnetic Encoding for which NCTE holds the patent.

This encoding turns the shaft into the primary sensor. For creating the permanent magnetic field, a current impulse is sent through the shaft equalising the orientation of all magnetic moments. The current usually has a strength of several kiloamperes and depends on the shaft’s diameter. It lasts few milliseconds. The induced magnetic field has long-term stability (step 2).

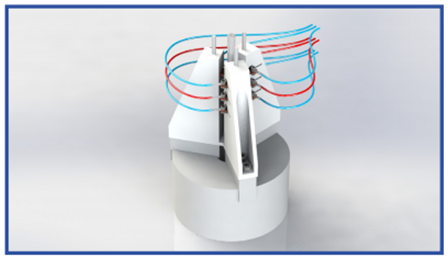

Secondary sensor unit and pairing

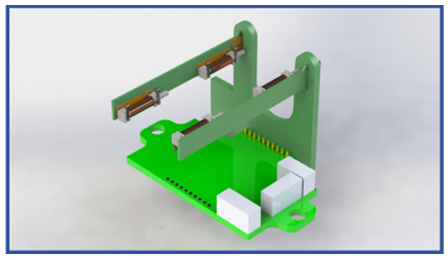

The reading unit is a static mini-sensor measuring the changes of the magnetic field without contact at a distance of several millimetres. The torque-induced changes of the magnetic field are very small (ca. 150 μT – 200 μT), therefore they are measured with a very precise measuring unit. This unit consists of magnetic field sensors as well as electronic components and a non-magnetic casing (step 3).

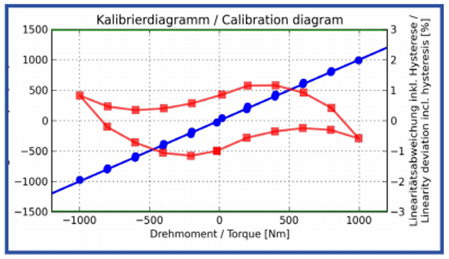

The last step is sensor calibration. The calibration of the entire sensor system takes only a few seconds and is very suitable for serial production (step 4).

In the last step both primary and secondary sensors are integrated in the product (step 5). The entire design can be adapted to the case of use. The OEM-design allows the system’s use even in the smallest spaces. The electronic parts can even be placed inside hollow shafts.

Advantages of non-contact sensors

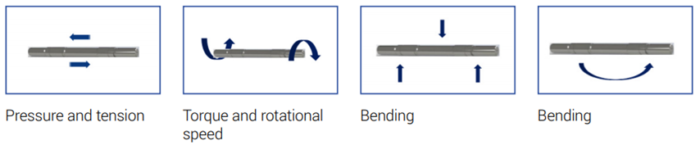

Magnetostriction technology allows for non-contact measurement of torque, force, shear or bending (static/dynamic) in test rigs or applications. Magnetic field technology can also be combined with conventional measuring techniques like rotational-speed measurement or active temperature compensation.

Main characteristics of non-contact technology:

- The existing shaft becomes the primary sensor, the secondary sensor can be designed as needed.

- Measurements are performed non-contact without cables or wear

- The patented magnetic encoding has long-term stability.

Advantages for the user:

- No need for adapting the original shaft design; the client keeps full control of the mechanical properties and saves the cost for adaptation.

- The secondary sensors occupy very little space; they can be adapted to the use case and find room even in hollow shafts.

- With its cost structure and scalability, the technology is suitable for use both in test stand and in serial production.

- The sensors deliver precise measurements even when exposed to strong vibrations, temperatures up to 125°C and under permanent temperature load with externally mounted electronics and rotational speeds of more than 40,000 rpm. Even the presence of oil or water will not compromise the sensors’ functioning.

- Magnetic field measurement is non-maintenance and even overloads will not damage the sensors.