Petrochemical industry using edge computing for machine condition monitoring

Introduction

The petrochemical industry produces products of tremendous value through labor-intensive and complex processes. Any unexpected equipment failure may result in a production shutdown and significant losses. With Industry 4.0 becoming a key development trend for manufacturing industries, the petrochemical industry is beginning to incorporate smart manufacturing, and leverage data insights. Prowave, with three decades of experience in equipment vibration research, collaborated with ADLINK to develop a new machine condition monitoring system for a large Taiwan petrochemical company. The result was increased reliability and safer operation of their production equipment

Reduced costs and payback periods spur adoption of machine condition monitoring solutions

Prowave successfully helped a major petrochemical company in Taiwan incorporate a machine monitoring system operating across multiple production sites. The system not only enables the company to stay on top of the operating conditions of the production line equipment but also generates additional benefits.

Smartization in manufacturing is still in the early stages, so many manufacturers are hesitant to introduce smart systems into their production process. In particular, machine condition monitoring systems are not considered revenue-generating equipment. Moreover, given their high upfront cost and long payback period, manufacturers generally take a wait-and-see attitude toward their adoption. However, there is a hidden side to development. If we look closely at current market developments, we will find market-leading manufacturers have long engaged in building up machine condition monitoring systems. This usage vouches for the value of these systems.

Four major benefits of machine condition monitoring

- Consistently reliable production line operation Production equipment is the most valuable revenue-generating asset to manufacturers. A machine condition monitoring system helps ensure the uninterrupted operation of production equipment so manufacturers can maintain product quality and production yield. It can prevent unexpected equipment failure that typically results in production shutdown and shipment delays, damaging business reputation.

- Significantly reduced maintenance cost A machine condition monitoring system will immediately issue an alert when detecting a warning sign of equipment failure. Factory managers can then take preventative action and root out the cause of the problem for minimal cost. Not only does this save manufacturers from the cost of replacing failed units but it can also effectively extend equipment life and maximize manufacturers’ return on investment.

- Ensuring labor safety A machine condition monitoring system can use smart monitoring solutions to remotely monitor the conditions of machines operating in hazardous environments such as at high altitudes or with toxic gas. It eliminates the need for human inspectors and reduces the chance of labor safety incidents.

- Driving smart transformation using big data analytics Equipment condition data collected by a machine condition monitoring system can serve as the basis for analysis by backend platforms to help factory managers make production plans and drive digital transformation for the corporation.

High-performance system precisely captures equipment condition

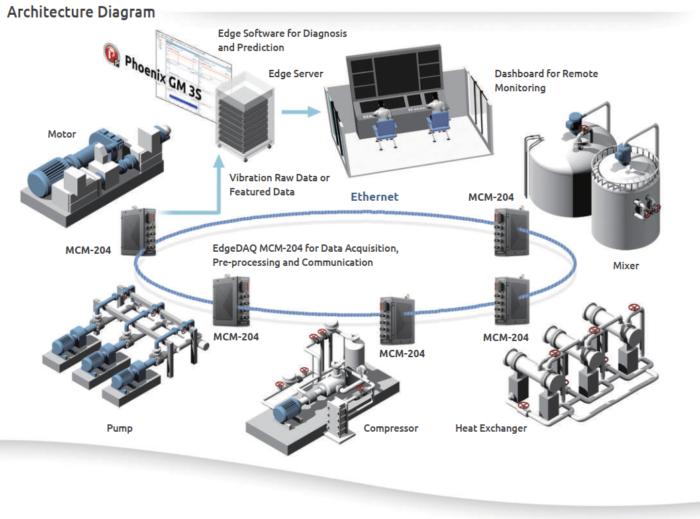

In light of the above benefits, Prowave built the machine condition monitoring system for the petrochemical company in Taiwan using the ADLINK MCM-100 and MCM-204. Featuring high resolution and high bandwidth, the MCM-100 and MCM-204 meet the system requirements for machine vibration detection. Their built-in RJ-45 Ethernet ports significantly shorten cabling distance and therefore minimize signal interference. With 4-CH 24-bit 128kS/s simultaneous sampling analog input, different machines can easily connect to form an Internet of Machines. The MCM-100, powered by an Intel Atom® x7-E3950, is suitable for use as a workstation at manufacturing sites. The MCM-204, featuring an ARM Cortex-A9, can perform edge computing, and its small footprint also allows easy integration with the production equipment on site.

ADLINK’s high-performance hardware supports Prowave’s vibration detection technology developed through long-term devotion to work at its best. In this case, the machine condition monitoring system Prowave built for the petrochemical company analyzes data collected from on-site production equipment in real-time. The vibration thresholds at which the system will issue a warning for critical events can be customized based on user requirements. Furthermore, Prowave provides complete maintenance service. It will perform annual system calibration based on on-site operation conditions after the system is put into place. Prowave will also build vibration models for the production equipment to enable more precise analysis and maintenance going forward.

Professional manufacturer selects the system for its high quality and high performance

A slew of global machine condition monitoring system providers took part in the tendering process of the petrochemical company, which is also

an equipment manufacturer and production line system expert itself. The system jointly created by ADLINK and Prowave was approved and

selected by the tender project managers over the other competing systems from leading global firms. They are now working together to put the

system in place at the petrochemical company’s plants. Aside from the petrochemical industry, the system is also ideal for the semiconductor,

display panel, pulp and paper, and other large-scale manufacturing industries. With the system, factory managers will be able to leverage real-time

machine condition monitoring to stay on top of production equipment health and take the first step to smart transformation.