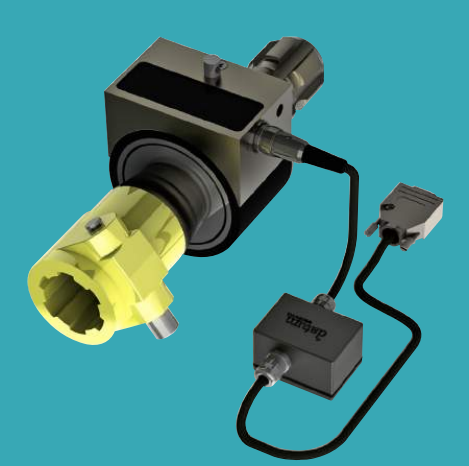

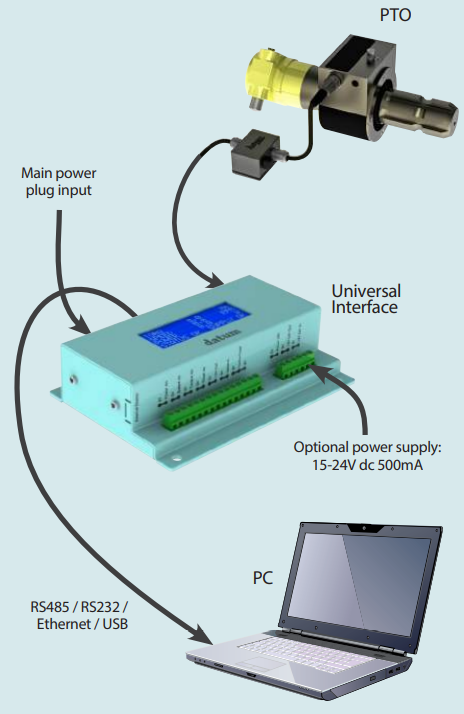

Datum Electronics Series 420 PTO (Power Take Off) Shaft Torque and Power Monitoring System will monitor and log the torque, shaft speed and transmitted power accurately when testing new systems driven from all standard PTO Shafts.

The tractor’s PTO or stub shaft transfers power from the tractor to the PTO-driven machine or implement. Power transfer is accomplished by connecting a drive shaft from the machinery to the tractor’s PTO stub shaft. Common examples include elevators, grain augers and silage blowers. The PTO and drive shaft rotates at 540 rpm (9 times/sec.) or 1,000 rpm (16.6 times/ sec.) when operating at full recommended speed. At all speeds, they rotate in proportion to the speed of the tractor engine. Measurement and Monitoring

Efficient measurement and monitoring of this power can be a useful tool in research and analysis into the performance of a tractor transmission. It highlights efficiency savings measurement and control.

PTO series 420 system performance and benefits:

- Power Monitoring

- Robust Design for use in field applications

- IP 65

- Easy Installation

- Accurate Results (0.5% Accuracy)

- Direct USB Interface into PC or laptop

Specifications

| STANDARD SPLINE CONFIGURATIONS | |||||

| Male / Female | 13/8” x 6 spline | ||||

| Male / Female | 13/8” x 21 spline | ||||

| Male / Female | 13/4” x 6 spline | ||||

| Male / Female | 13/4” x 20 spline | ||||

| OPERATING SPEED | |||||

| 540 / 1,000 rpm as standard (up to 3,000rpm if required) | |||||

| POWER RATING (MIN) | |||||

| Standard 13/8” shaft configurations | |||||

| Measures Power 135HP or 101kW at 540rpm | |||||

| Measures Power 253HP or 188kW at 1000rpm | |||||

| Standard 13/4” shaft configurations | |||||

| Measures Power: 190HP or 141kW at 540rpm | |||||

| Measures Power: 350HP or 261kW at 1000rpm | |||||

| PERFORMANCE | |||||

| Non-Linearity | +/-0.1% FSD | ||||

| Non-Repeatability | +/-0.05% FSD | ||||

| Sample Rate | 1 to 100 samples per second | ||||

| Output Baud Rate | 9600 baud | ||||

| Transducer output interfaces: | |||||

| Serial data via RS485 | |||||

| Transducer output data: | |||||

| Torque | Shaft RPM | Shaft Temp | Diagnostics | ||

| POWER SUPPLY | |||||

| Transducer | 10-24Vdc 250mA | ||||

| Transducer and Interface | 15-24Vdc 400mA | ||||

| TORQUE RATING | |||||

| Measures Torque up to a maximum of 1,800Nm on all standard 13/8” shafts | |||||

| Measures Torque up to a maximum of 2,500Nm on all standard 13/4” shafts | |||||

| SIGNAL INTERFACE OUTPUTS | |||||

| Digital | |||||

| RS485 | Serial data | ||||

| RS232 | Serial data | ||||

| Ethernet | Data | ||||

| MODBUS UDP | Serial data | ||||

| USB Type Mini B | Serial data and configuration | ||||

| USB Type A | Data logging | ||||

| Analogues: | |||||

| All four of the PTO Transducer’s analogue output channels can be configured for any of the following settings by the user: 4-20mA configured 4-20mA (4-12-20mA): +/-10Vdc, +/-5Vdc, 0-10Vdc or 0-5Vdc | |||||

| A typical configuration arrangement would be as follows: | |||||

| Channel 1 – Torque | from 0-500Nm as 4-20mA | ||||

| Channel 2 – Speed RPM | from 0-100-rpm as 0-5Vdc | ||||

| Channel 3 – Power | from 0-5000W as 4-20mA | ||||

| Channel 4 – Spare | |||||

| Display: | |||||

| Torque | Speed RPM | Power | |||

| ENVIRONMENT | |||||

| Thermal Stability of Gain per 10˚C | 0.02% | ||||

| Thermal Stability of Zero per 10˚C | 0.02% | ||||

| Normal Specification Range | 10 to 60˚C | ||||

| Operating Range | -10 to +70˚C | ||||

| Storage Range | -35 to +75˚C | ||||

| Environmental Protection | IP54 (see RS425 for IP67/68) | ||||

| Electromagnetic Compatibility | EN61326-1:2006 (IEC61000-4), IEC60945) | ||||

Q&A

Related Products

The Torque Transducer can either be supplied from our standard range with DIN flanges up to 30KNm or as custom units up to any size...

NCTE magnetostrictive technology Contactless, wear-free and precisely Measuring static and dynamic torque Made in Germany EMC Directive 2014/30/EU, EN 61000-6-2:2019-11, EN 61000-6-4:2020-09, EN 61326-1:2013-07, EN...

The latest technology Datum Electronics M425 non-contact rotary Torque Transducers have been designed to fit with most applications and solutions requiring rotary torque measurement.

The Datum Electronics Series RS425 non-contact rotary torque transducers have been designed to fit easily in line with any drivetrain or test bed using either...