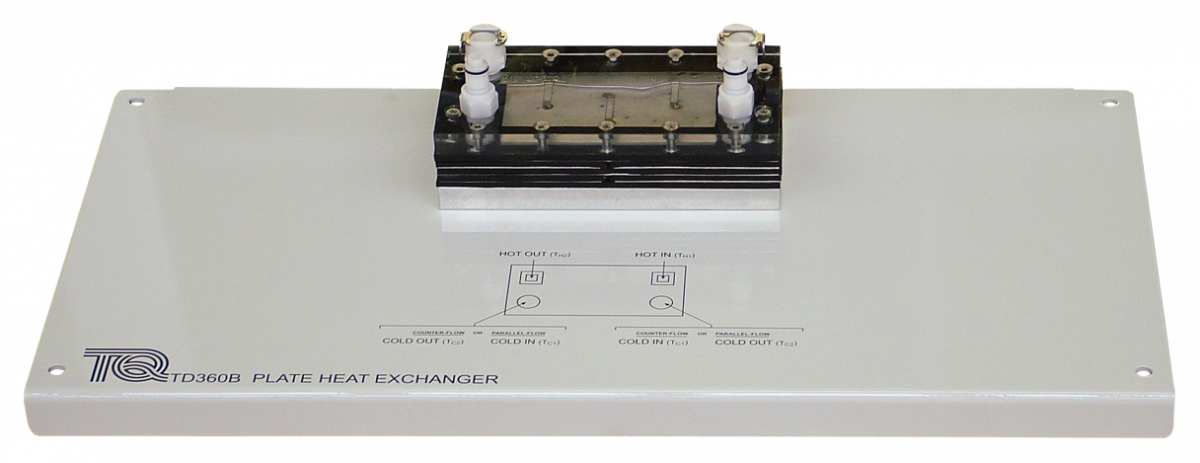

Key Features:

- One of a set of optional heat exchangers for use with TecQuipment’s TD360 Service Module

- Popular type heat exchanger, used in industry but designed for teaching

- Simple and safe to use – foolproof fittings allow students to change and connect the heat exchanger quickly and easily – needs no tools

- Clear outside casing, so students can see its construction

- Bedplate with a clear schematic diagram to help students understand how to connect the heat exchanger

- Corrosion-resistant materials for use with ordinary clean water at safe temperatures

Description:

- This heat exchanger is a set of metal plates separated by spacers (gaskets).

- The plates and gaskets have holes that make the hot and cold flow run on alternate sides of the plates, therefore transferring heat.

Learning Outcomes:

- Demonstration of heat transfer from one fluid to another through a solid wall

- Energy balance and efficiency calculations

- Demonstration of parallel-flow and counter-flow operation of heat exchangers

- Measurement of the heat transfer coefficient, and the effect of fluid flow rates and the driving force (temperature differential) upon it

- Introduction to the logarithmic mean temperature difference in heat exchangers

- Comparison of different types of heat exchanger in terms of performance, size and relative cost (only if two or more optional heat exchangers have been bought)

Specifications

- Dimensions and weight: 500 mm x 260 mm x 100 mm and 2.4 kg

- Transparent top cover

- Four stainless steel plates each 0.005 m2 and 1 mm thick with flow disturbers on surface

- EPDM rubber plate spacers

- Heat transfer area 0.02 m2

- Connection to Service Module with quick connectors

For details see the catalog below: