| Type |

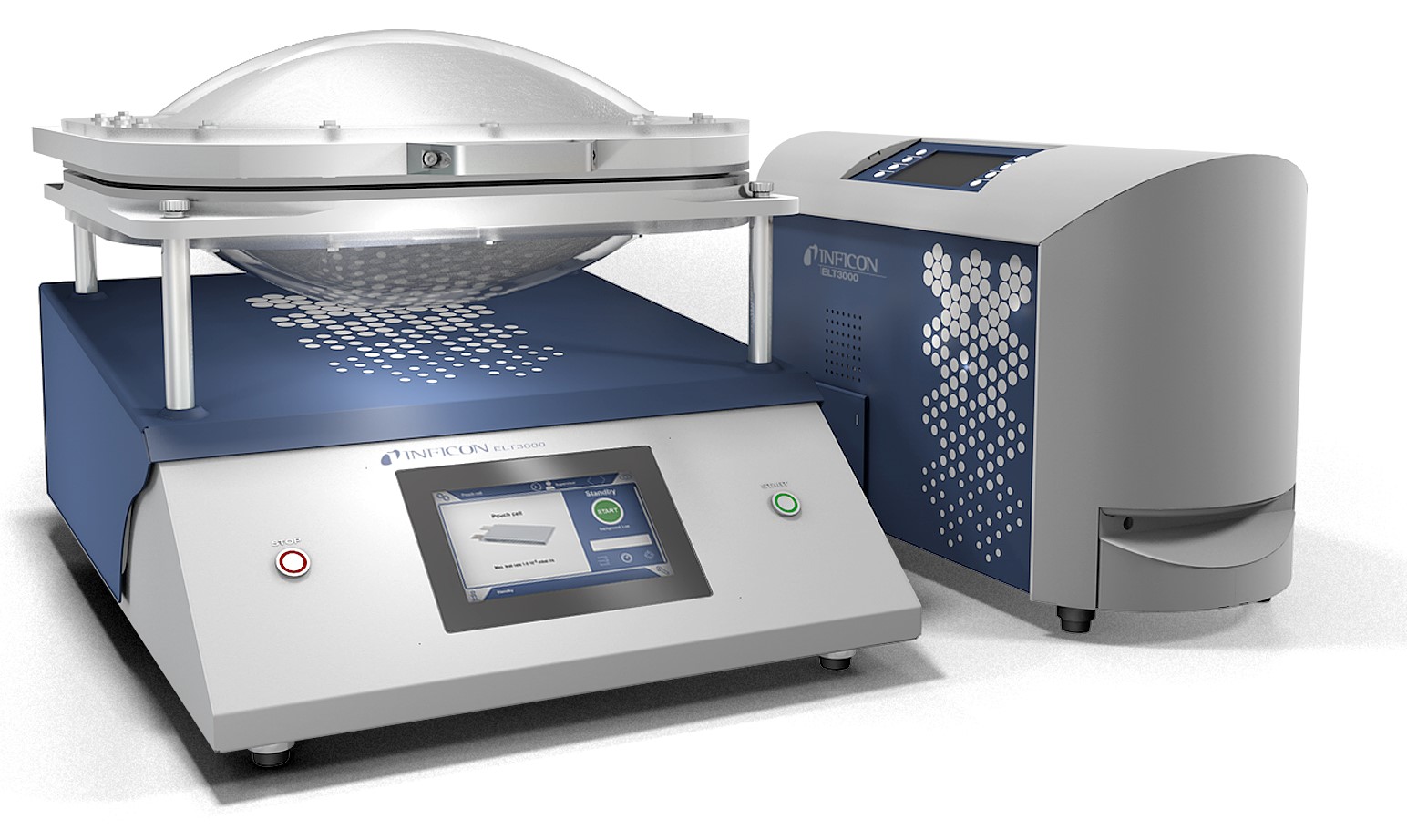

ELT3000 |

| Smallest detectable leak rate |

1×10-6mbar·l/s (Helium equivalent leak rate) |

| Measuring range |

3 Dekaden |

| Leak rate units |

mbar·l/s, atm·cc/s, Pa·m3/s |

| Detection sensor |

Quadropol Massenspektrometer (2 Kathoden) |

| Time unit ready for measurement |

<180 s |

| Serial interfaces |

USB 2.0; M12 (for connection I/O1000); RJ45 (network connection) |

| Interface via I/O1000 Modul |

10 digital Inputs; 8 digital outputs; RS232 |

| Operating temperature |

10°C – 30°C (50 – 86 F) |

| Ingress protection class |

IP20 |

| Dimensions Gas Detection (W x H x D) |

610 mm x 300 mm x 380 mm (24 in x 12 in x 15 in) |

| Dimensions Control Unit (W x H x D) |

700 mm x 540 mm x 250 mm (27.6 in x 13.7 in x 6.4 in) |

| Weight |

65 kg (144.5 lbs) |

| Operating language |

English, German, Korean, Chinese, Japanese |