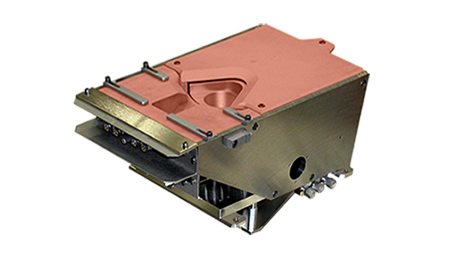

Temescal’s patented PopTop® e-beam sources offer enhanced convenience, reliability, and throughput in applications ranging from optical and microelectronic production to compound semiconductors and specialized R & D coatings. The key to these performance enhancements is Temescal’s pneumatically actuated “PopTop” crucible cover, which is raised automatically before turret rotation. The net benefit is the virtual elimination of cross-contamination.

Key Features

- Movable crucible cover, which rises before crucible is rotated

- Pneumatically driven, low-impact cover motion

- Lip of cover recessed around exposed pocket

- Raised structures on underside of cover interlock with crucible web walls

- Virtual elimination of cross-contamination

- Minimal deposition on web walls and on cover margins around exposed pocket

- Reduced risk of damage to source and turret indexer

- Removable/replaceable cover and crucible enable easy source convertibility

- Enhanced crucible cooling improves thermal stability during evaporation

- Adjustable internal and external pole piece extensions optimize beam spot control, regardless of beam position

- Ultra-stable magnetics eliminate the need to regauss magnetic parts following source disassembly

- Power ratings: 1-10 kW (Model 2PT) and 1-12 kW (Model 3PT)

Specifications

| Dimensions | Refer to Drawings |

| Weight | Model 2PT: 44.2 lbs. (20 kg) |

| Model 3PT: 50.3 lbs. (22.8 kg) | |

| Rotation torque | 10 in.• lbs. (11.5 kg • cm) |

| Max. bakeout temp. | 302° F (150° C) |

| Max. power | Model 2PT: 10 kW |

| Model 3PT: 12 kW | |

| Acceleration voltage | 4–10 kV |

| Operating pressure | |

| Maximum | 5 x 10-4 torr (6.7 x 10-4 mbar) |

| Minimum | 1 x 10-8 torr (1.33 x 10-8 mbar) |

| Beam characteristics | |

| Beam deflection | 270° |

| Beam spot size/shape | From tight oval to diffuse oblong |

| Sweep capability | Longitudinal and lateral |

| Evaporation rate | See chart below |

| Installation requirements | |

| Input power requirements | |

| Filament current | 70 A at 12 V ac |

| Emission current | 0–1.5 A at 4–10 kV dc (10 kW max.) |

| Cooling water | |

| Max. temperature | 68° F (20° C) |

| Flow rate | 3.0 gpm (0.19 l/sec.) |

| Max. inlet pressure | 100 psi (6.89 bar) |

| Min. delta pressure | 50 psi (3.45 bar) |

| Feedthroughs | |

| High voltage | Two HV feedthroughs rated for 12 kV at 70 A |

| Octal | One octal feedthrough rated for 110 V at 3 A per lead |

| Dual pass | One dual-pass feedthrough with 3/8-in. (9.5-mm) OD tubes |

| Rotary | One rotary-motion feedthrough with 1/4-in. (6.4-mm) dia. Shaft |

Q&A

Related Products

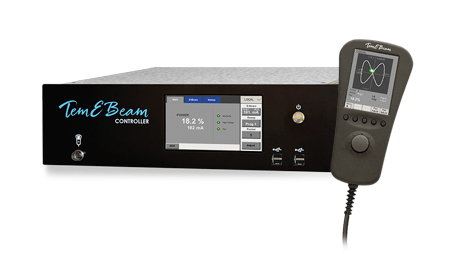

The TemEBeam Multi-function Integrated Electron Beam Controller, a unique new component-level solution for simplifying electron beam systems. With the TemEBeam controller you can consolidate components,...

Our 6 MHz crystals are used with all INFICON controllers and monitors. Our 5 MHz crystals can be used with 5MHz instruments only

Whatever electron beam evaporation system you’re currently using, you can transform it into an automated system with Ferrotec’s new FerroVac controller. The FerroVac controller integrates...

The Carrera series of power supplies uses primary switched mode technology to offer high efficiency and fast arc detection and recovery in a compact unit....